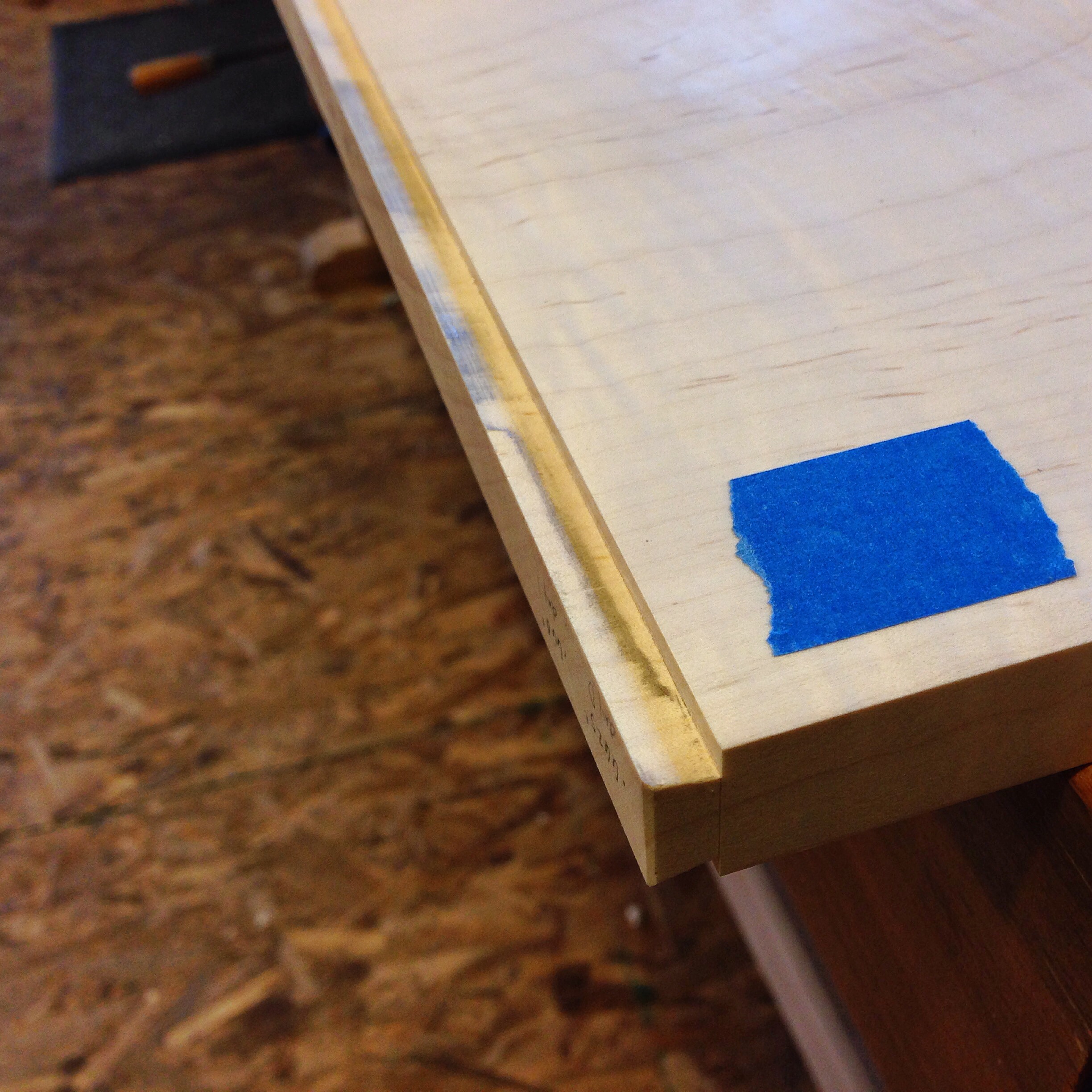

I have a confession to make: I like using glue blocks. Why not? They strengthen assemblies, like the underside of this base for a casepiece I'm working on. I use them in places where they won't be seen. But they should still look good.

Multifaceted

Final shaping of the underbevels on the top of a case piece. The goal is flat facets and crisp transitions.

Coping With Cove Molding

I'm working on some cove molding today and wanted to share this clamping setup I used to hold the molding after ripping it to width. Because the cove is already milled, the molding is tippy and hard to secure while bringing it all into very consistent width with a block plane. A few pieces of mdf and a few clamps are used to hold the molding upright while planing. It turned out to be a really solid setup.

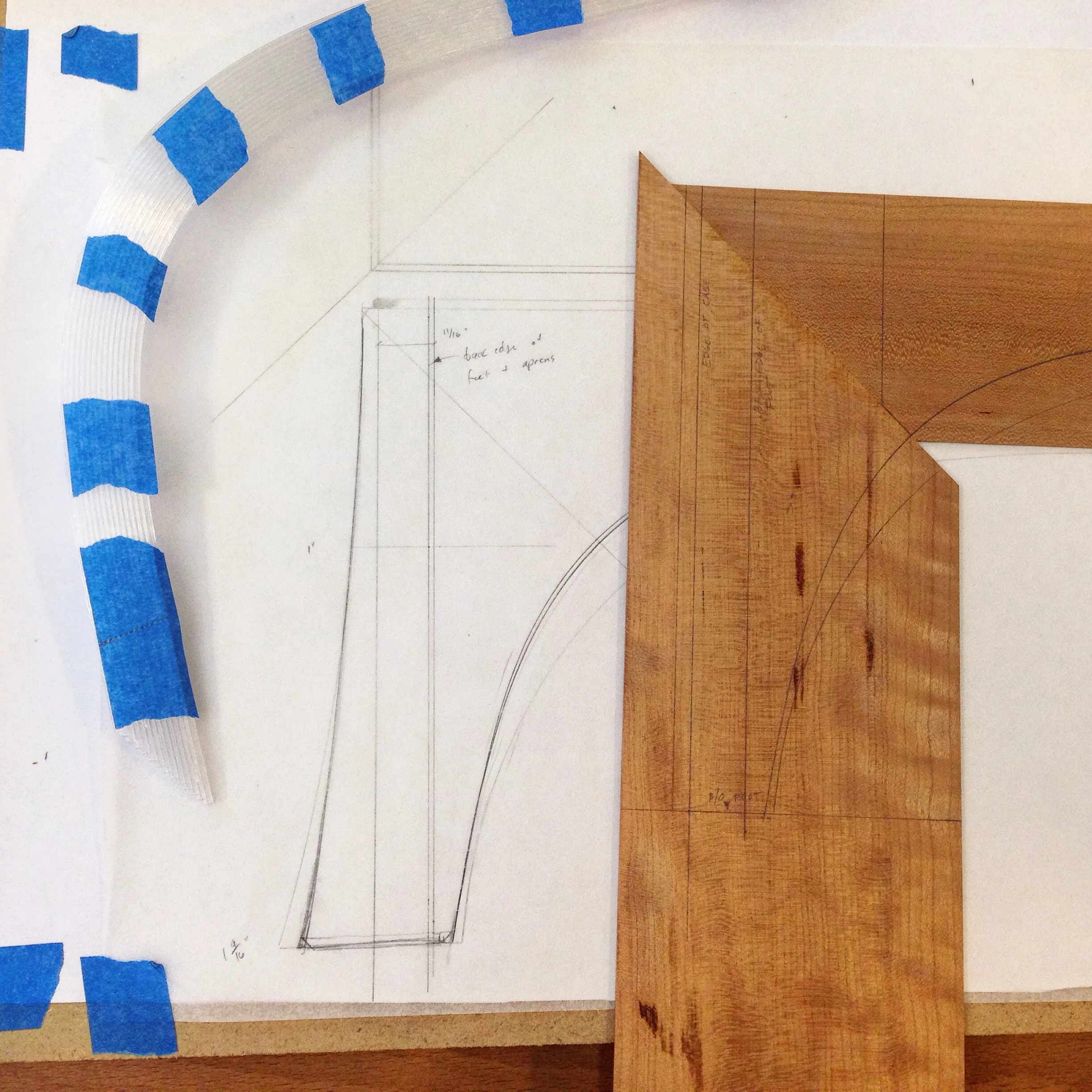

It All Starts With A Drawing

I've always struggled with how best to transfer a drawing to template stock in order to cut/shape the template. I've tried a bunch of different ways, and the method that I prefer is to generate the different shapes with drawing aids that can be fixed, such as this ships curve or a drawing bow. I then lay out reference lines and points on the template stock and draw the different curves with the drawing aids.

A Little Help From a Pencil

On to fitting the tapered sliding dovetails. I cut these on my router table as if the mortises were not tapered, and then form the tapers by hand with chisels. It is extremely helpful to rub pencil lead on the tapered edge of the dovetail mortise. When inserted into the mortise, the lead rubs off onto the pins (or tenons, I'm not sure what to call the male part), revealing the high points.