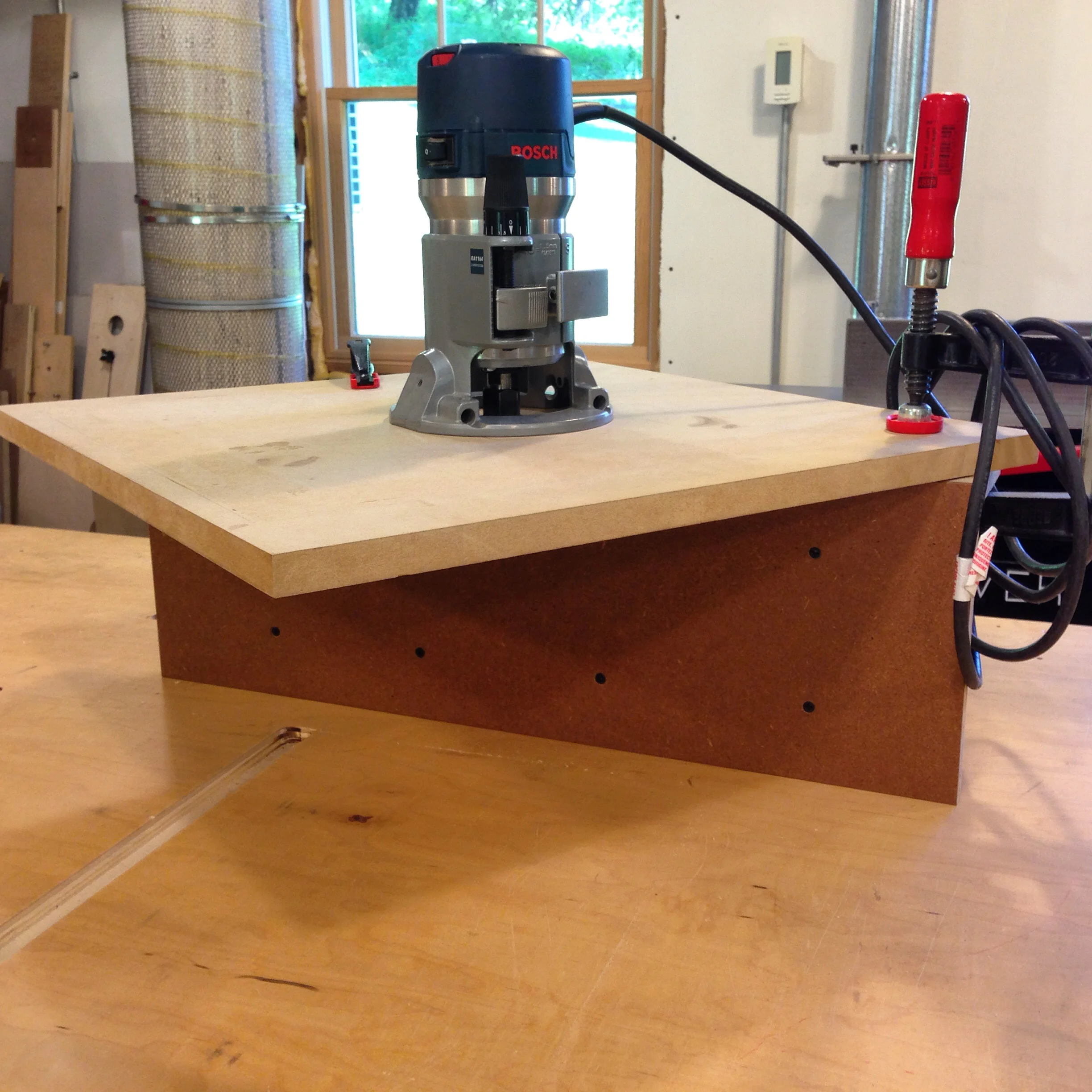

I'm working on some tapered sliding dovetails for a case piece. My router "table" setup (shown upside down here) for routing the male part is pretty basic - just a piece of mdf with attached router base. The fence is the best part of the whole setup - flat, square, rigid. But, I'm showing this because I have found (the hard way, of course) that it's good practice to keep a setup intact until you absolutely need to dismantle it to do something else. That way if you realize you forgot to run one piece, just go back to the setup and run it. So this will sit here on my outfeed until all the dovetails are fit.

Bug Holes

I've been noticing something unusual on the bark of a small aspen that fell down a few years ago. The trunk is in Livvie's pooping grounds, so I rarely venture there. I decided to check it out today and discovered that what I've been seeing is the frass from wood boring insects, pushed out the holes behind the bugs, like caulk out of a tube of caulk.

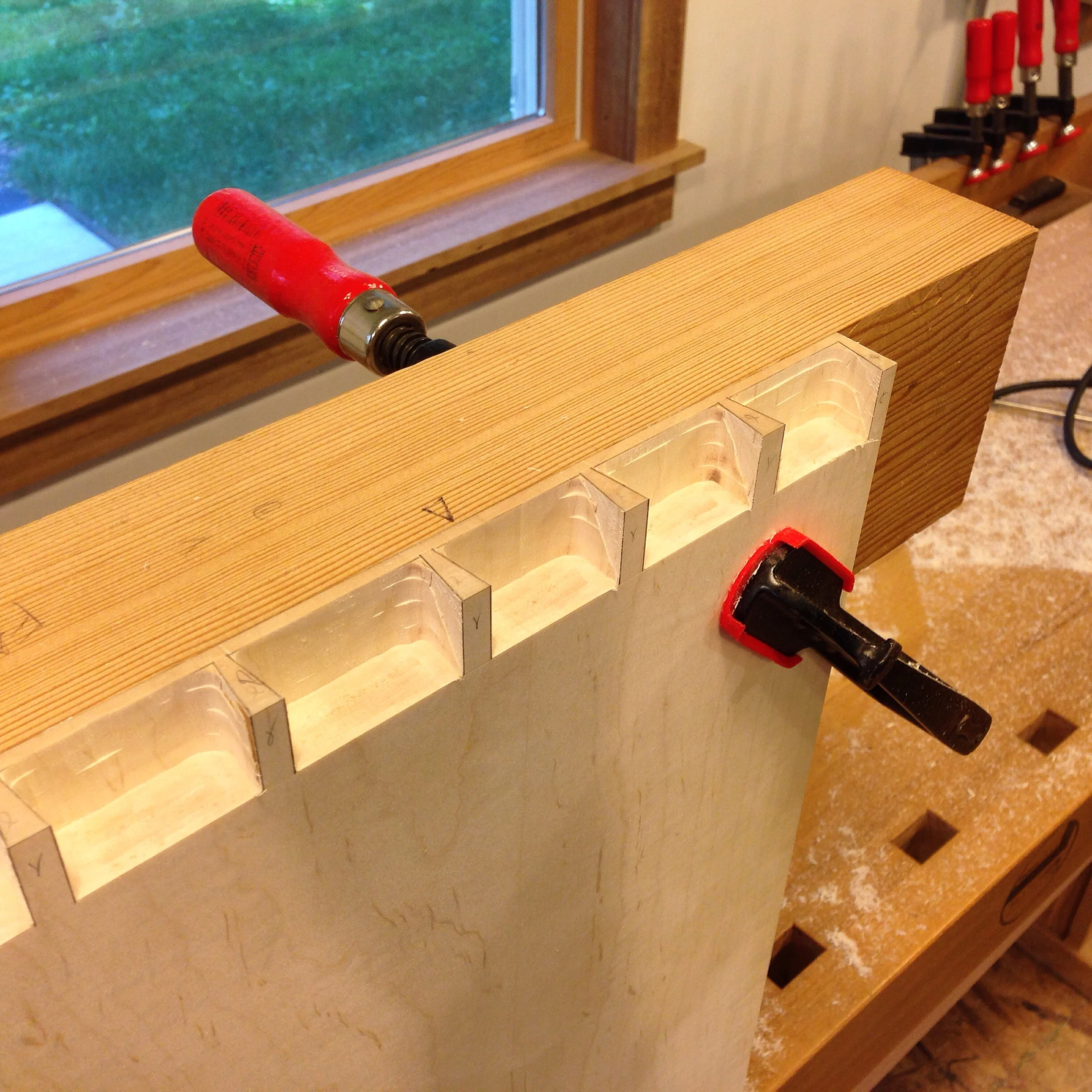

Hand Tools + Power Tools

When cutting half blind dovetails, I prefer to use power tools to waste away the bulk of the waste. On this case side, I used a palm router freehand to get as close to the layout lines as possible. The rest is chisel work, which isn't always fun in curly maple.

Thinking About Precision

A few years ago when I really started to think critically about my work, I discovered that the stock tablesaw fence I was using was out of square relative to the saw table. The melamine faces on the fence couldn't be adjusted, so I removed the faces and added wood faces. Now I can true up the face of the fence, checking with square and straightedge to make sure it is flat and square to the table.

High Visibility

One great thing about working with curly maple: layout lines jump out at you. No need for crazy lighting setups.