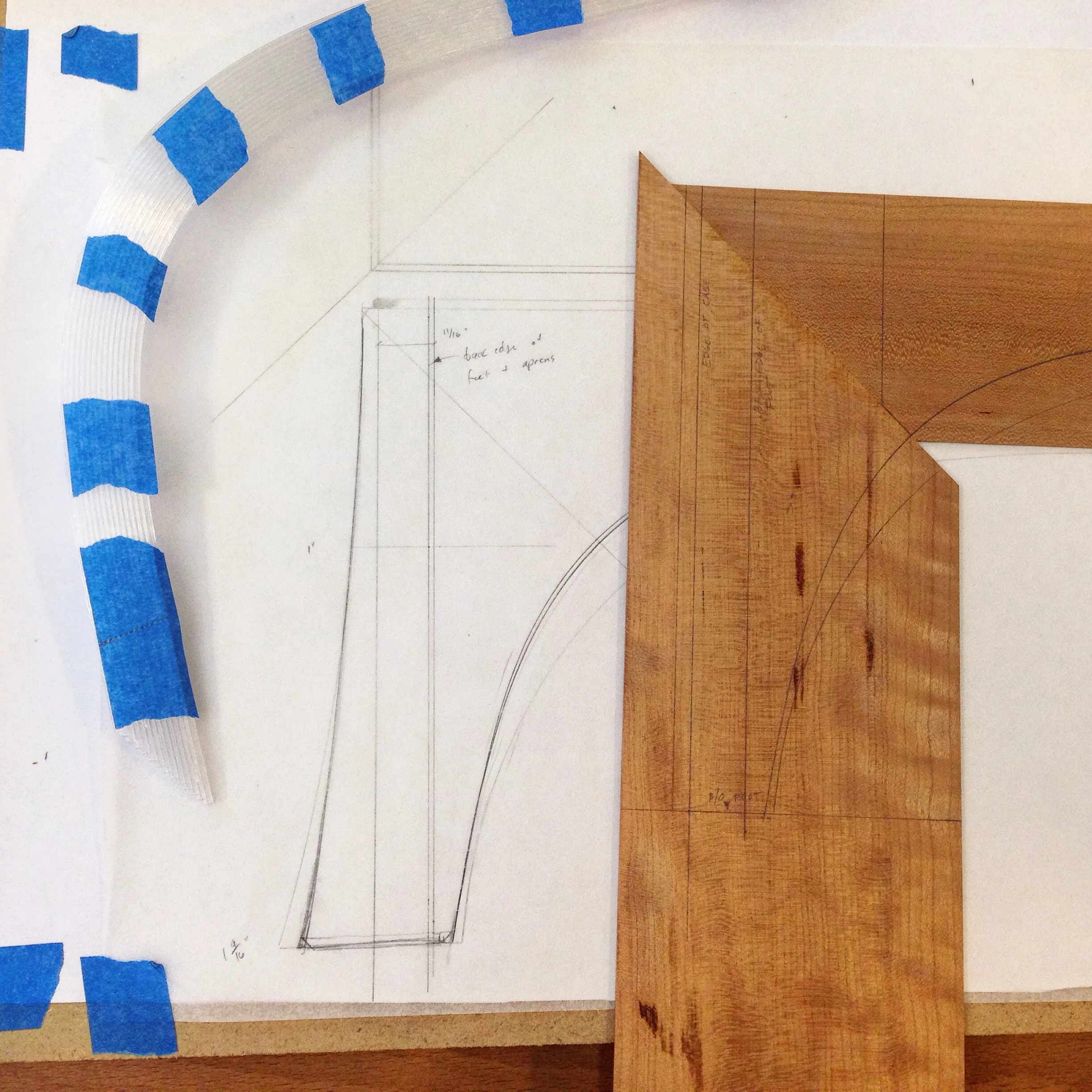

I've always struggled with how best to transfer a drawing to template stock in order to cut/shape the template. I've tried a bunch of different ways, and the method that I prefer is to generate the different shapes with drawing aids that can be fixed, such as this ships curve or a drawing bow. I then lay out reference lines and points on the template stock and draw the different curves with the drawing aids.

A Little Help From a Pencil

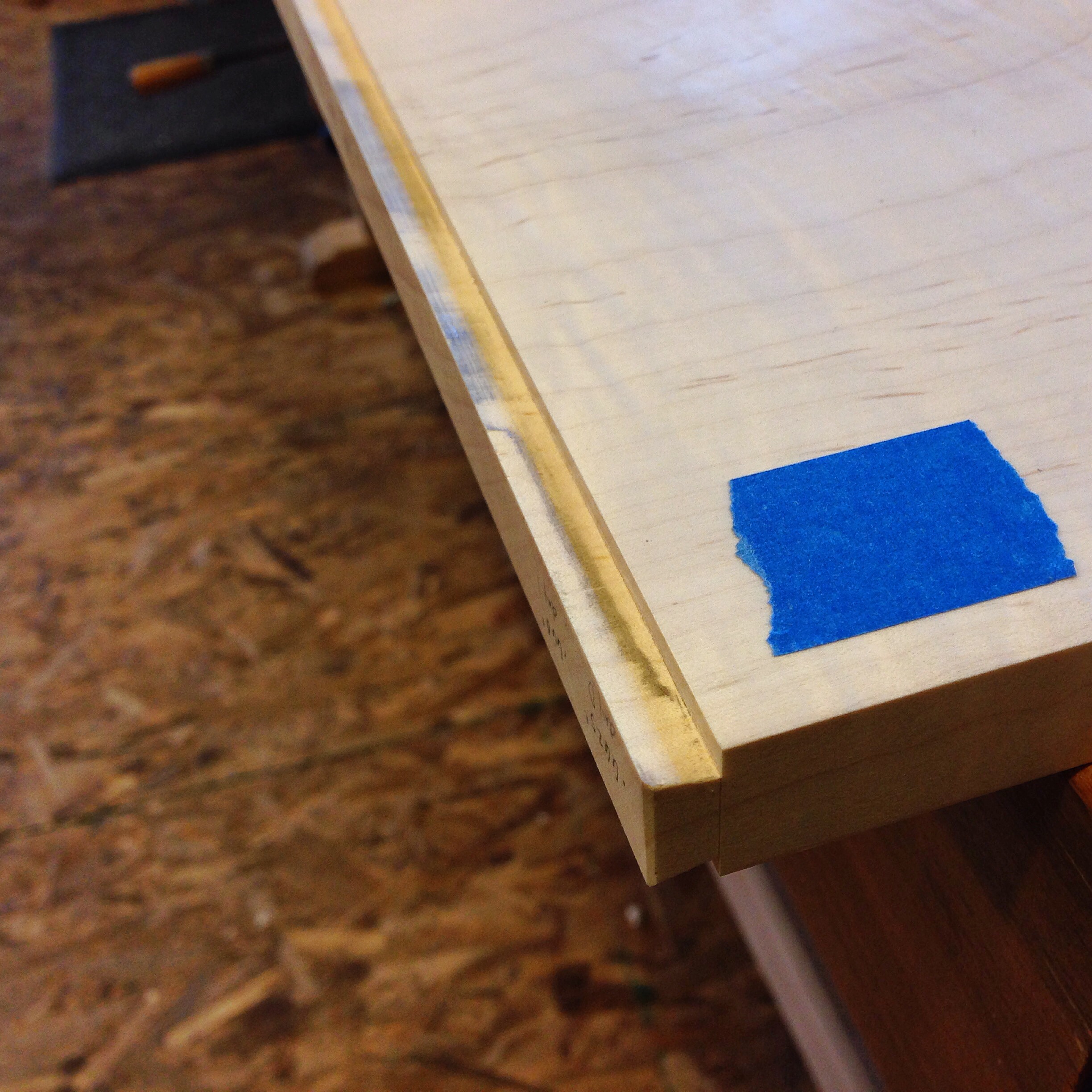

On to fitting the tapered sliding dovetails. I cut these on my router table as if the mortises were not tapered, and then form the tapers by hand with chisels. It is extremely helpful to rub pencil lead on the tapered edge of the dovetail mortise. When inserted into the mortise, the lead rubs off onto the pins (or tenons, I'm not sure what to call the male part), revealing the high points.

Learning The Hard Way

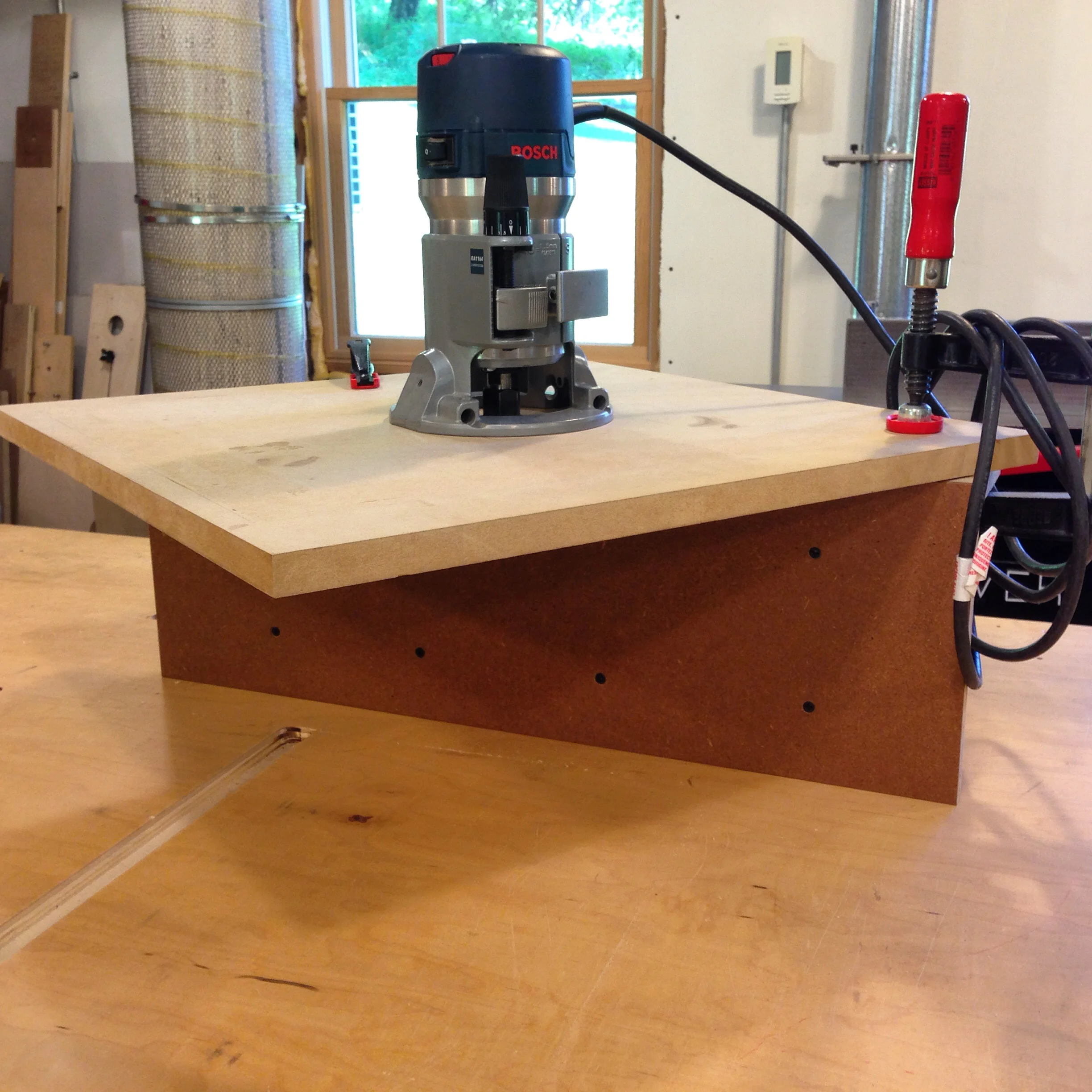

I'm working on some tapered sliding dovetails for a case piece. My router "table" setup (shown upside down here) for routing the male part is pretty basic - just a piece of mdf with attached router base. The fence is the best part of the whole setup - flat, square, rigid. But, I'm showing this because I have found (the hard way, of course) that it's good practice to keep a setup intact until you absolutely need to dismantle it to do something else. That way if you realize you forgot to run one piece, just go back to the setup and run it. So this will sit here on my outfeed until all the dovetails are fit.

Bug Holes

I've been noticing something unusual on the bark of a small aspen that fell down a few years ago. The trunk is in Livvie's pooping grounds, so I rarely venture there. I decided to check it out today and discovered that what I've been seeing is the frass from wood boring insects, pushed out the holes behind the bugs, like caulk out of a tube of caulk.

Hand Tools + Power Tools

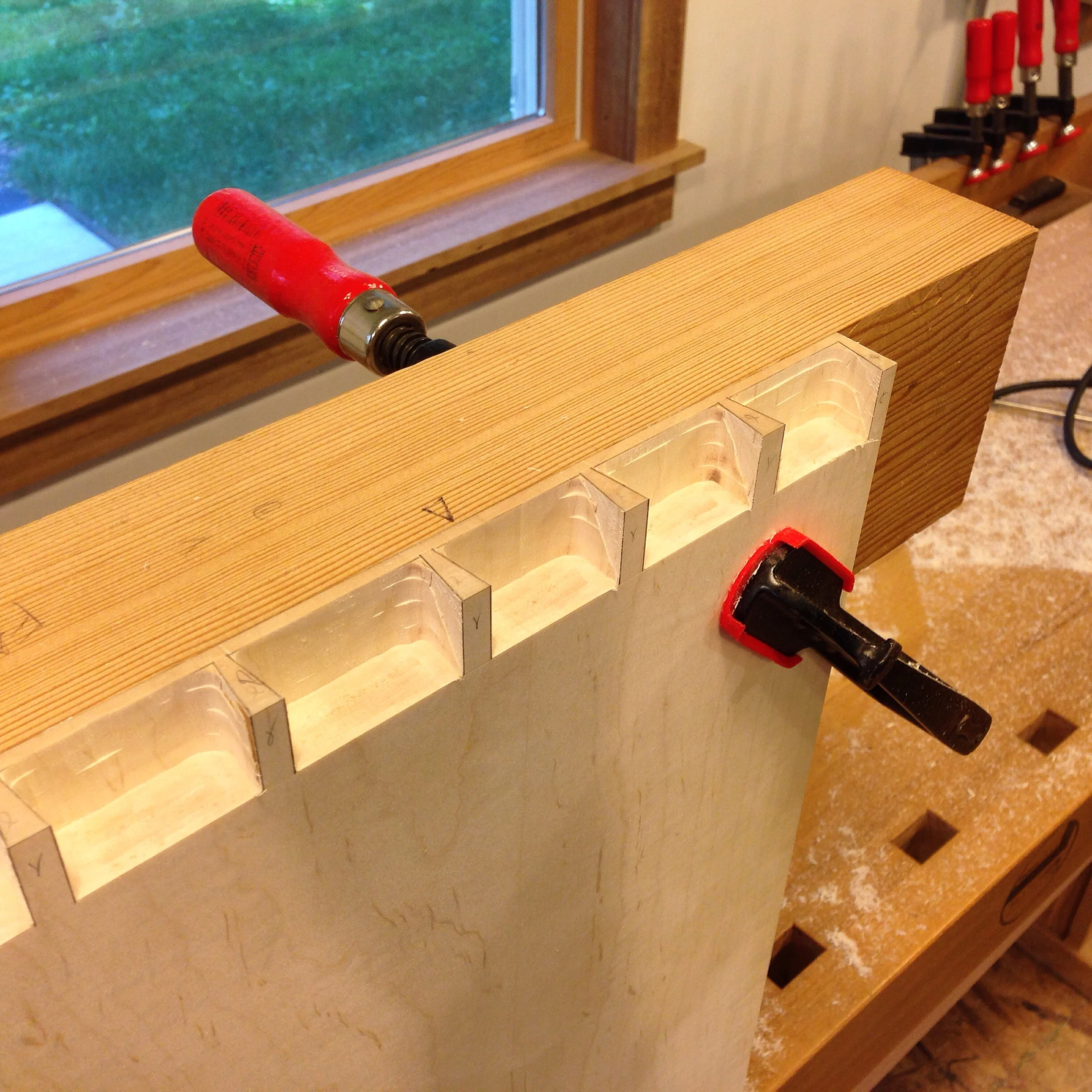

When cutting half blind dovetails, I prefer to use power tools to waste away the bulk of the waste. On this case side, I used a palm router freehand to get as close to the layout lines as possible. The rest is chisel work, which isn't always fun in curly maple.