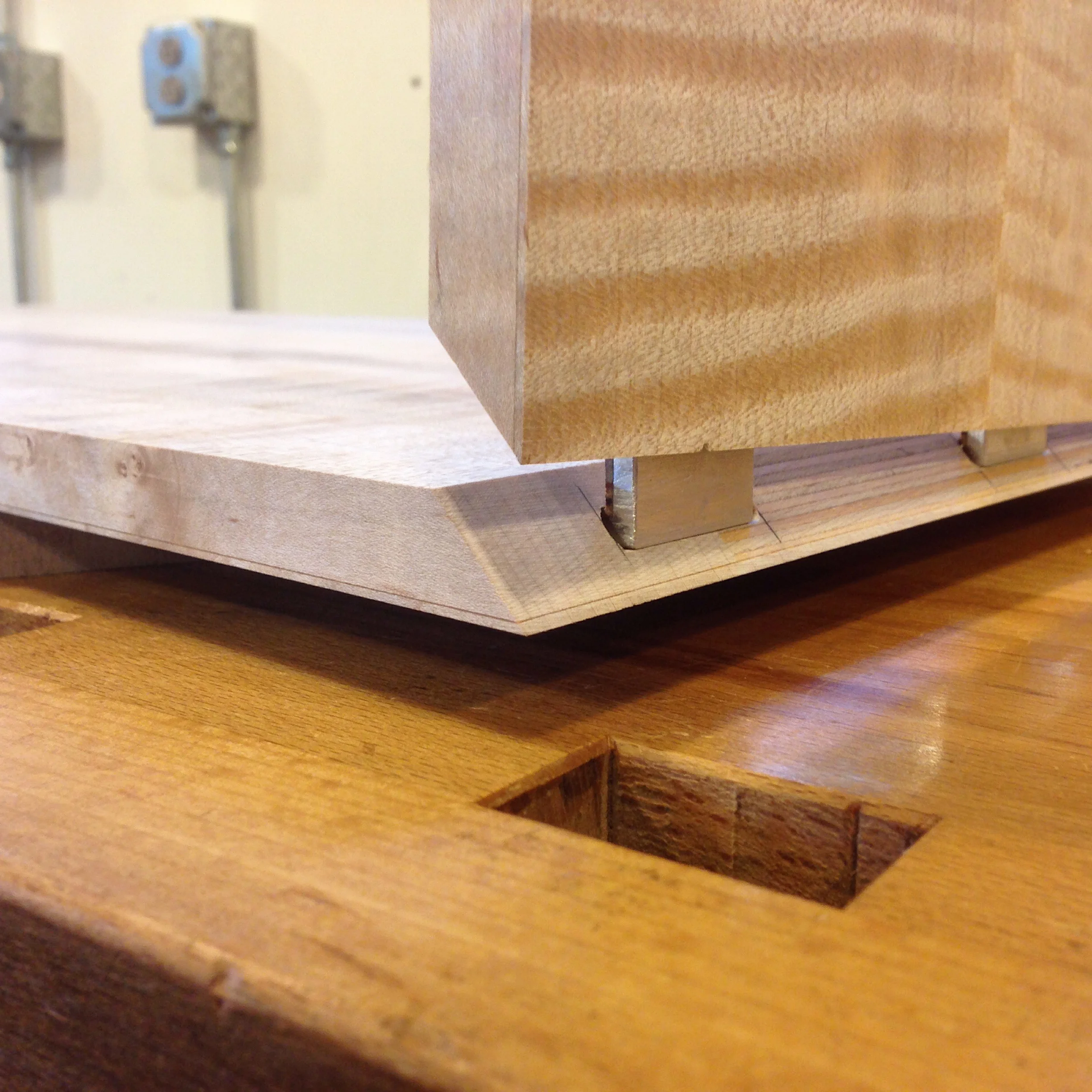

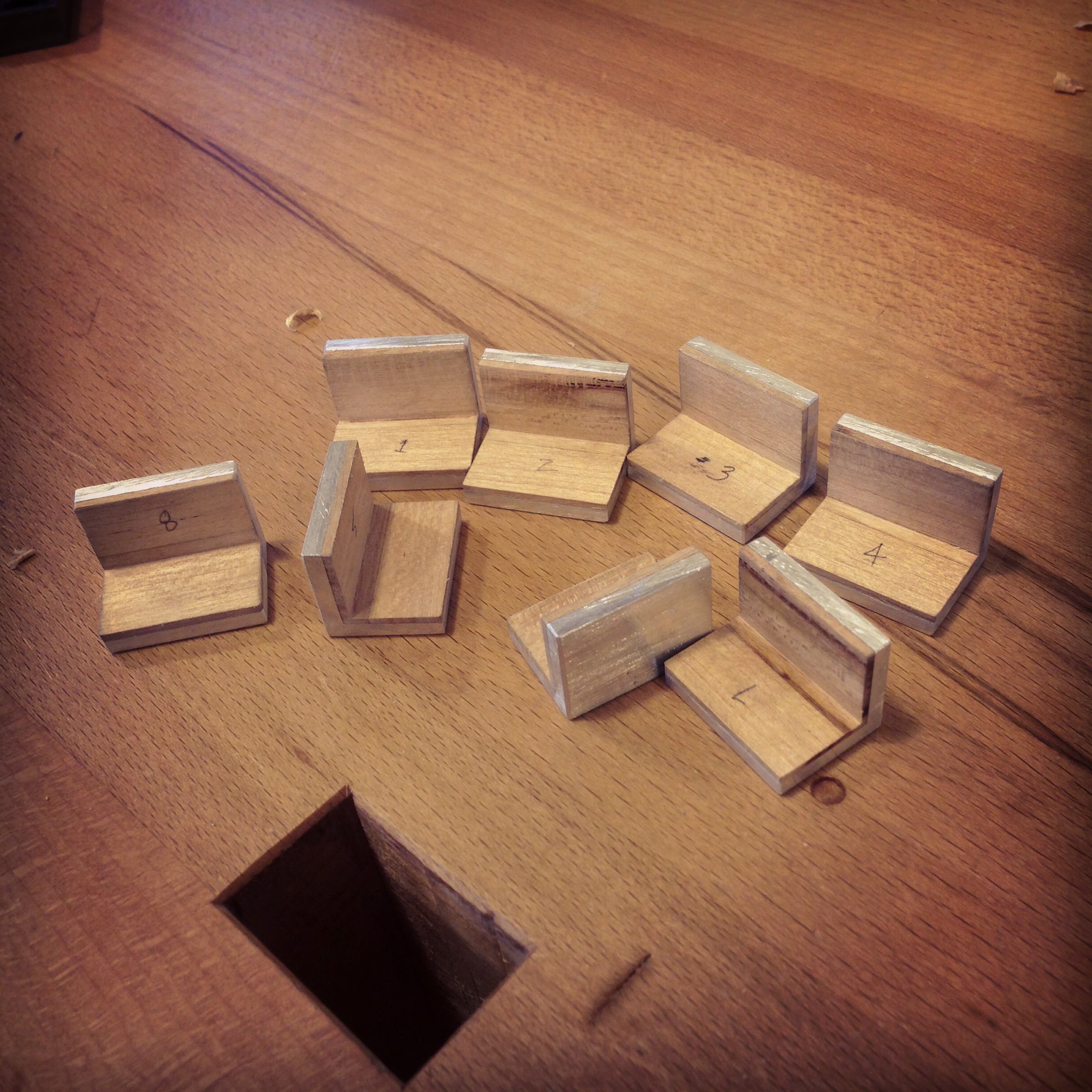

Here are some of those cherry/aluminum slip tenons in place. I'll use epoxy to secure the tenons into the mortises and regular PVA glue on the faces of the miters.

Slip Tenons With A Twist

Cherry stock laminated to 3/4" aluminum angle to reinforce the miter joints on the case. Thanks to Tim Coleman and Fine Woodworking magazine for the article detailing this technique. I'm liking it so far.

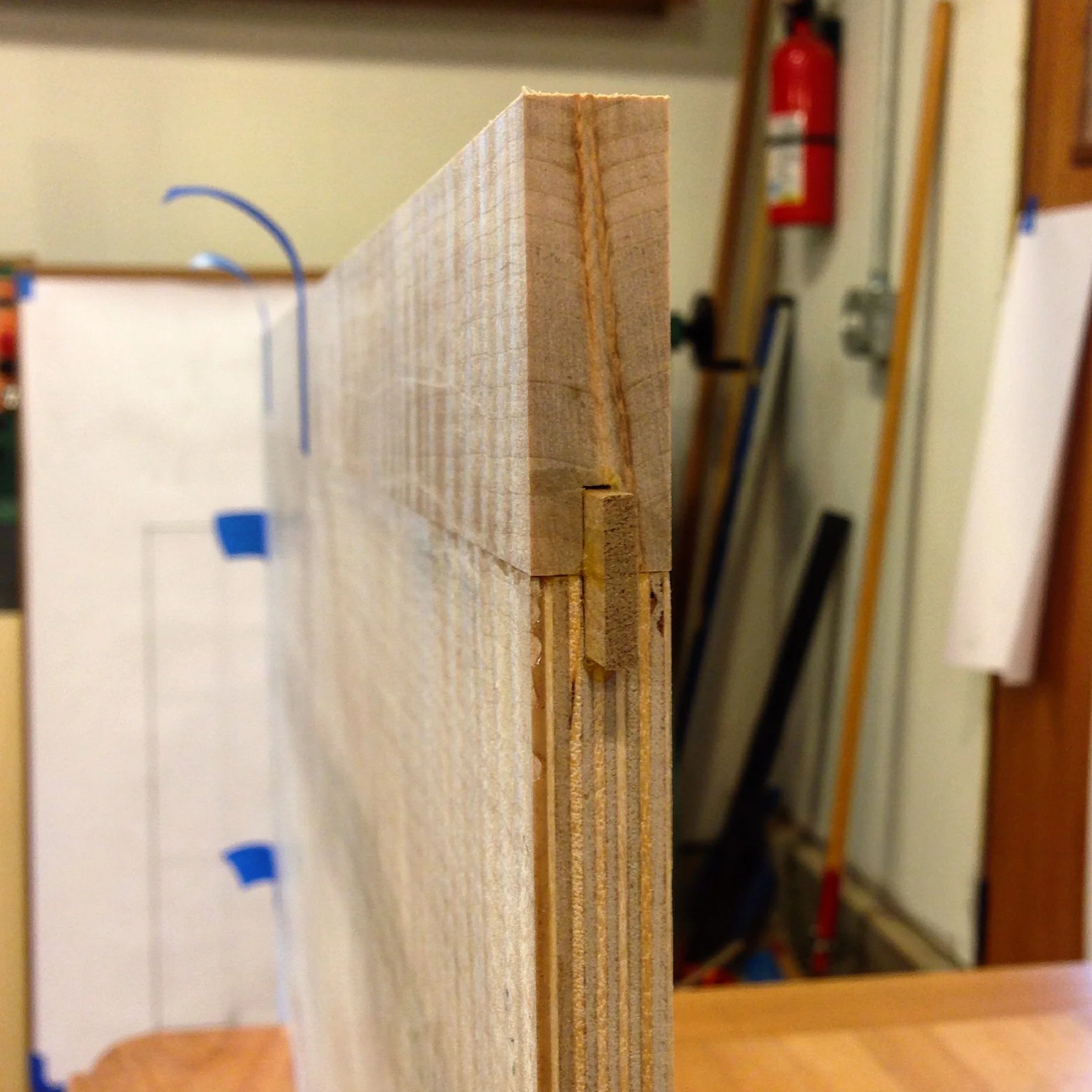

Splined Solid Edging

Almost finished with all the veneering. This is the case top, with inside veneer pressed and front solid edging applied (with spline). The edging has been flushed to both inside and outside faces (the outside "face" at this point is the face of the birch plywood I'm using as a substrate). I'm ready to press the outside, which will cover the solid edging. Later, that joint will be hidden by rosewood edging.

Flattening Veneered Panels

After pressing only the inside veneers on the top and sides, I work the veneered faces flat with a no. 62 with a cambered iron. I'm also shooting for consistent thickness for the top and side panels, so lots of stopping to check the thickness with calipers. If you look closely in the foreground you can see some numbers written on the panel - those tell me the thickness at points on the top panel. All three panels are now within .002" to .003" of eachother.

A Closer Look At Pressing

Here's a look at the case top panel, sandwiched between platens. Nice consistent adhesive squeeze out.