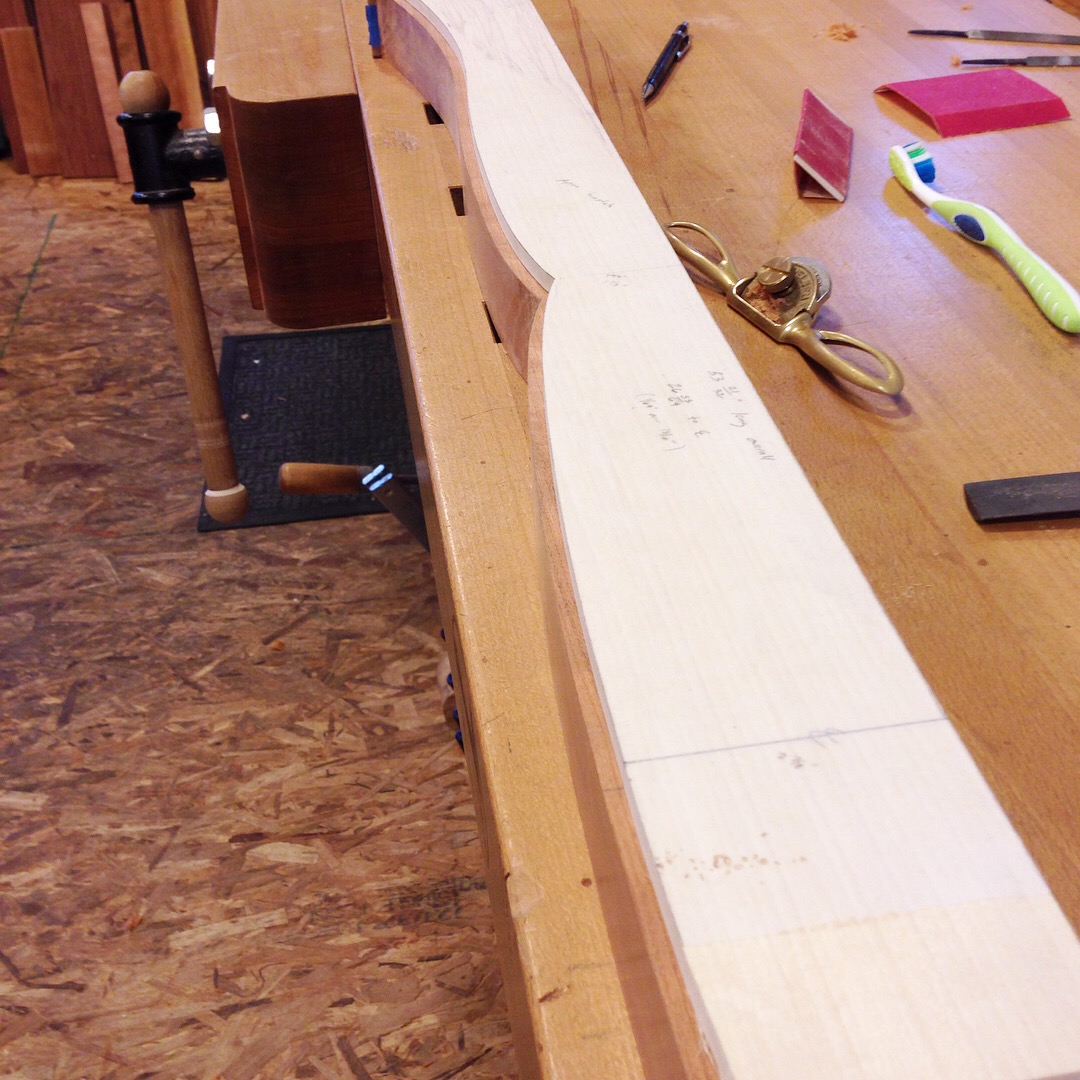

On to shaping the aprons. Again, using a pattern to layout the shape, rough out on the bandsaw and work to the line with hand tools. Working into this little cleft takes some careful hand work to get it to a sharp, pronounced point.

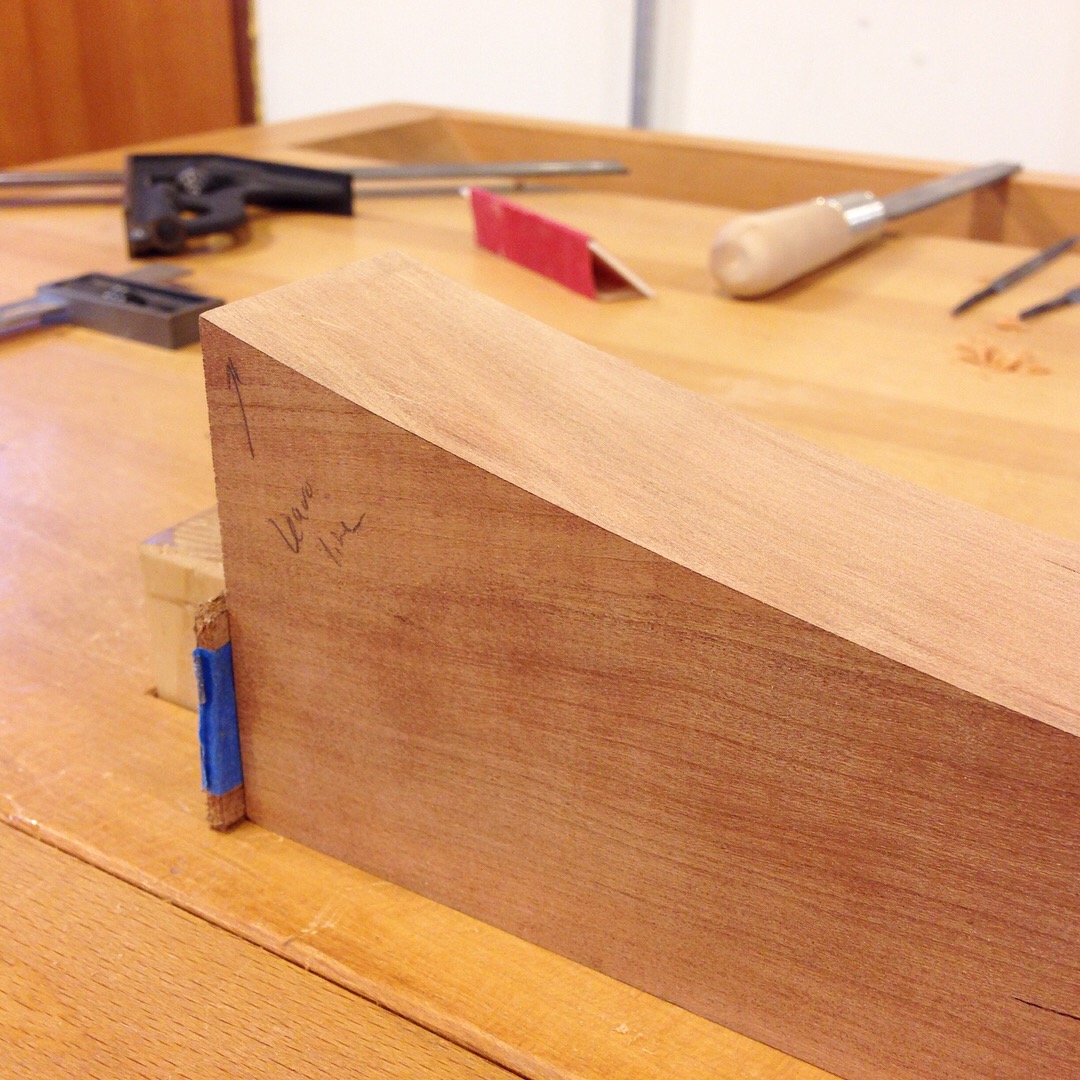

The slip tenons are done for now. I check them all for thickness and mark one end. The "1" on the end of this one tells me it is .371" thick, as measured with calipers. I keep them in a plastic bag so they don't see any changes in relative humidity (and therefore maintain their current moisture content/dimensions). The slips will be fine tuned to individual mortises later on, but they can take a break for now.