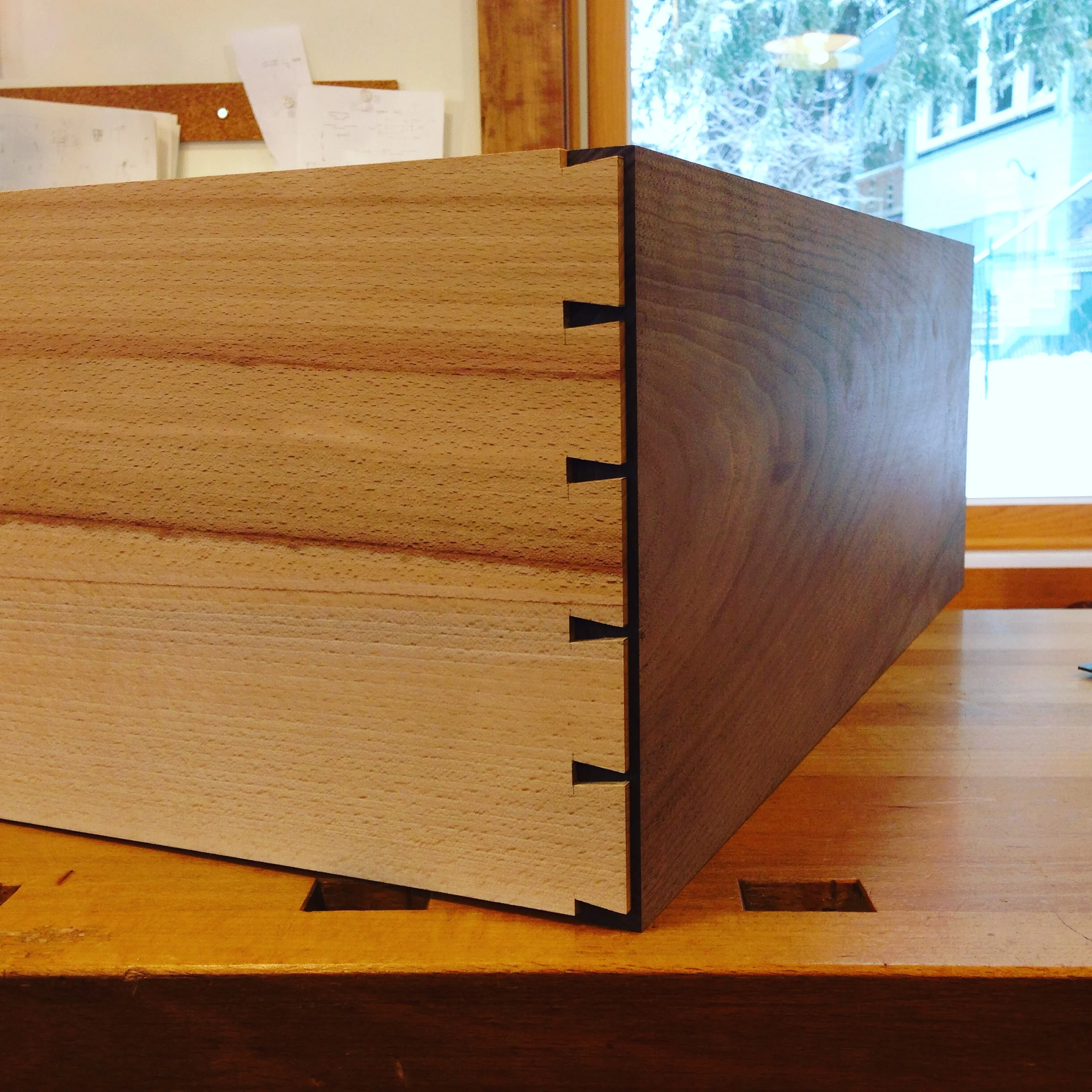

A successful test fit of beech drawer side to walnut front. Cutting dovetails is all about the process. From stock prep, to layout, to fine fiddling and everything in between.

Feel The Rhythm

One of the things I find with cutting dovetails is that I don't do it that often, maybe once every few months. So it can take some time to get that rhythm back. Sawing these drawer sides today and it definitely felt right (and showed).

Steel vs Wood

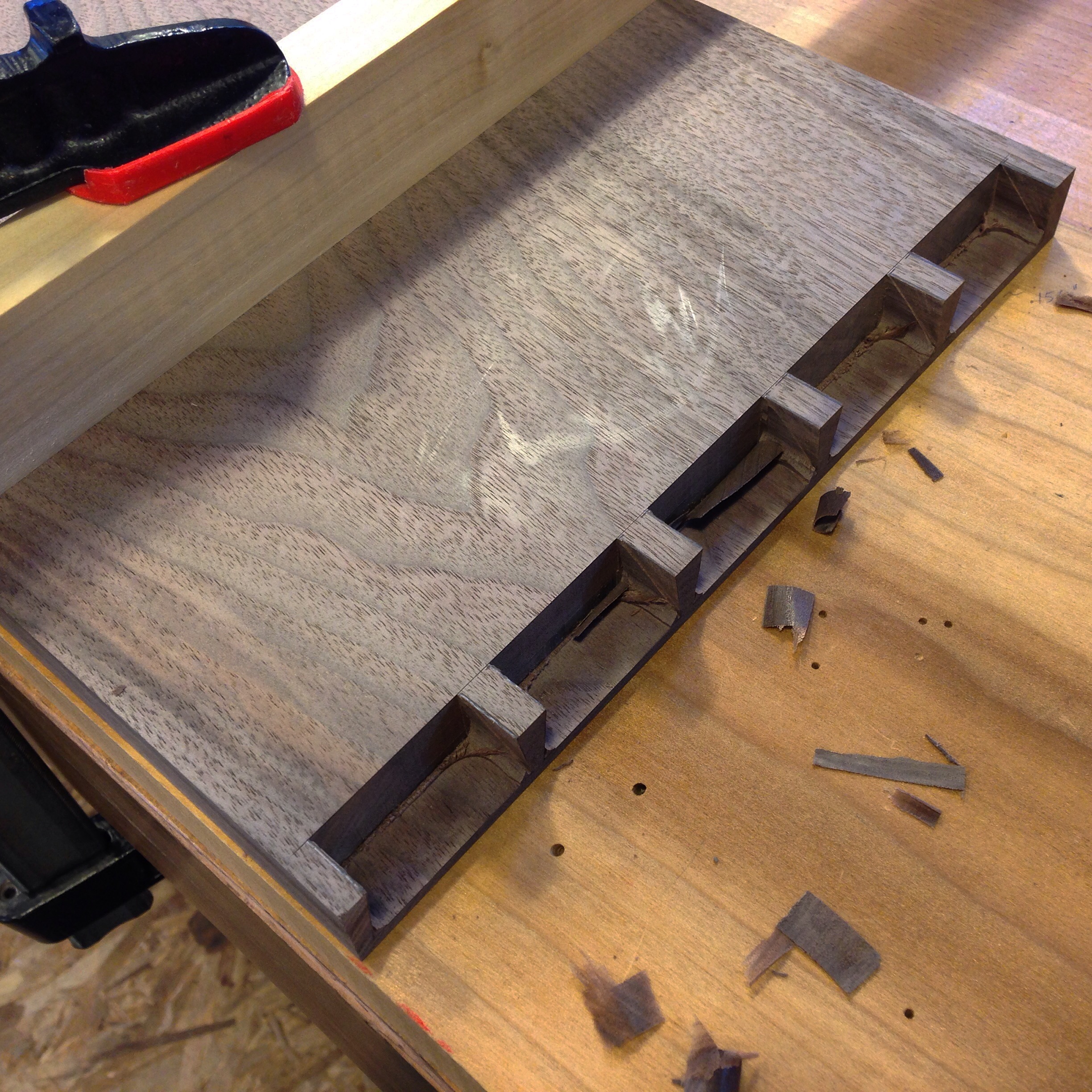

This walnut has some figure. Not a lot, and only in a few spots. But any chisel work in these figured areas is brutal. Here's my big chisel with nicely destroyed cutting edge. And this is after doing some grinding to remove the damage. Just trashed.

Deep Thoughts On Dovetails

Crisp dovetails start with crisp layout and marking. The rest is just grunt work.

Working Small Parts

The bead stock for the drawer fronts is hand planed to thickness and here I'm getting ready to shape the bead. I'll do the bulk of the shaping with a block plane and the finish with a scratch stock. Once again, holding the work is almost a greater challenge than the work that has to be done.